Is it time for warehouse Automation with Robots?

2023 State of Warehouse Labor Report

Newswire.com in 2023 conducted a survey of 400 light industrial business leaders in the area of distribution and fulfillment on their current business challenges. Labor shortages is the #1 issue facing warehouse/distribution operations.

64% of respondents said they had to forgo business worth more than 28% of their revenue due to staffing issues.

32% of respondents reported that wages had increased by 37% in the past year.

69% said they used temporary or flexible workers in 2022.

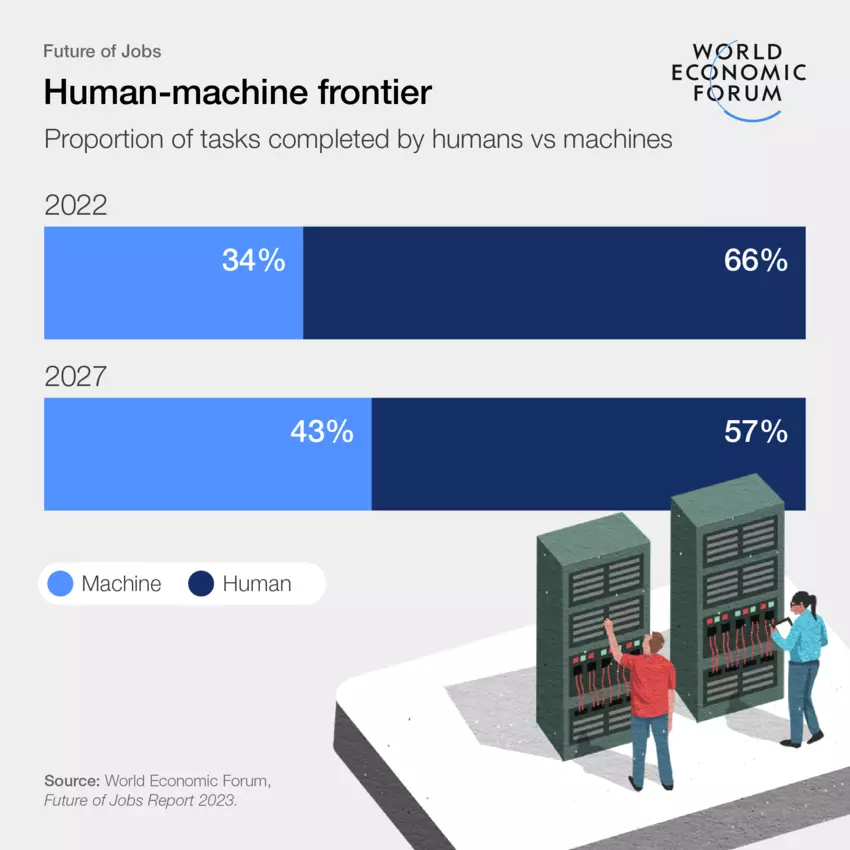

In another study called “The Future of Jobs” report 2023 by The World Economic Forum. In 2022 34% of all work was completed by machines with 66% completed by humans. In 2027 that number is expected to increase to 43% of all work will be performed by machines.

The cost of labor is going up, the cost of robots is going down. The technology and integration into existing systems has become easily adaptable and intuitive. The robots and accessories are reliable and easy to exchange. Peak and off season fulfillment is manageable and predictable with automation.

Now is the best time to implement automation and begin the benefits of lower operating costs and higher fulfillment rates. If you are in the 64% that had to turn down business last year.

Why Wait – When you can Automate

Mushiny Goods-To-Person Autonomous Mobile Robot AMR

- Reduce Labor Costs by 70%

- 3 times more efficient than manual labor

- Highly Flexible – add or remove robots, manage peaks

- Provide safe human-robot work environment

- 99% Picking Accuracy

- Rapid Deployment – get a full system in 16 weeks

- Return On Investment – less than 3 years

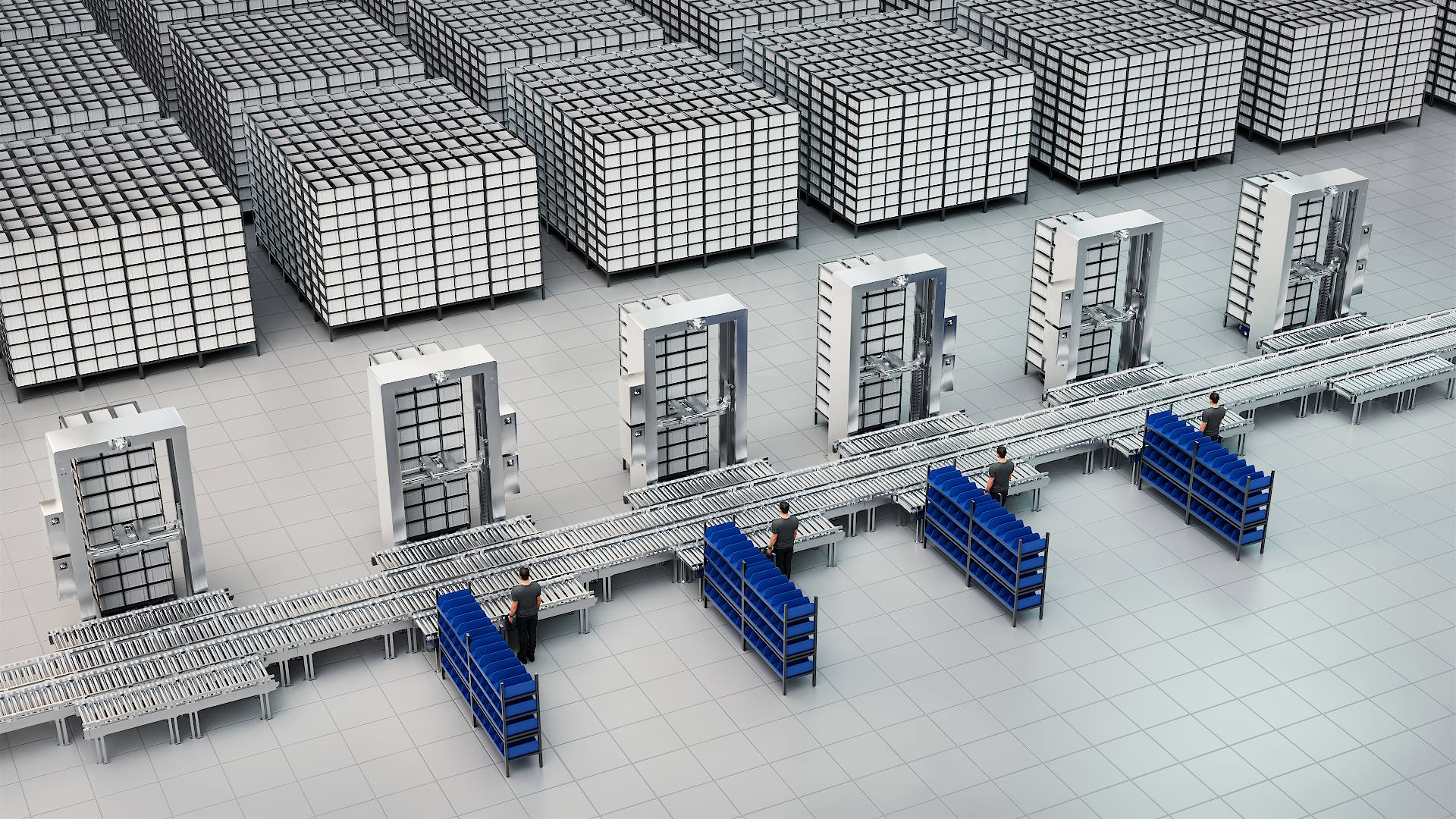

Mushiny Autonomous Mobile Robots are revolutionizing material handling in warehouses and distribution centers. Our Goods-To-Person Picking Robots have fast pick rates, up to 600 line items an hour. Flexibility to handle various product sizes. With a high load capacity and versatile shelf design, our AMR offers efficiency and flexibility in storing and retrieving goods in high throughput fulfillment operations.

Equipped with smart navigation technology, our AMR’s operate autonomously, reducing manual intervention and ensuring seamless movement throughout your facility. Safety features, including collision avoidance and obstacle detection, create a safe, secure work environment.

The user-friendly interface allows easy programming and monitoring, while cloud connectivity offers real-time data analysis and remote management capabilities. Experience increased productivity, space optimization, and improved safety with Mushiny Autonomous Mobile Robotics – a scalable and efficient solution for businesses of all sizes.

Mushiny Goods-To-Person MIX – Automated Tote Picking presents totes to an operator combined with piece/carton presentation from PODs and or Pallets in the same workstation. The MIX provides World Class throughput with minimal labor combined with High-Density storage efficiency and fast payback. Modular design allows for modifying product mix. Relocating is flexible and fast to implement changes to your operation.

MIX applications provide the greatest efficiency when:

- 70% of products are MIX Shelf Storage

- 20% products are on Pallet or AMR Shelf Storage

- 10% Manual picks and or order consolidation

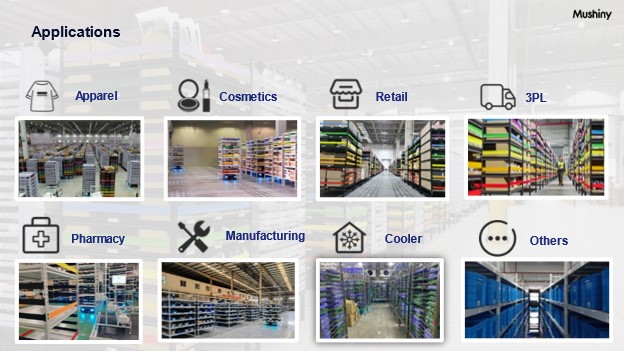

Applications:

Order Fulfillment: In e-commerce and retail fulfillment centers, shuttle AMRs play a vital role in the order picking process. Robots can swiftly transport products to order pickers and packers, reducing time spent walking, searching, recording and then all over again doing replenishment. Reduce your labor increase order output with Mushiny Picking Robots.

Goods-to-Person (G2P) Fulfillment: In G2P systems, shuttle AMRs bring the required items directly to the order pickers, eliminating the need for pickers to walk or drive through the warehouse to gather products. The system directs the operator on what to pick and where to put it, increasing accuracy and improving operator picking efficiency.

Inventory Management: Shuttle AMRs aid in inventory replenishment tasks. They can carry out routine stock replenishment from bulk storage areas to the picking stations, ensuring that products are readily available for order processing.

AS/RS Interface: Shuttle AMRs can interface with Automated Storage and Retrieval Systems (AS/RS) and Automated Guided Vehicles (AGVs), enhancing the efficiency of material flow between these systems.

Line-side Delivery: In manufacturing environments, shuttle AMRs are used to deliver components or materials to production lines, ensuring a continuous supply and minimizing downtime.

Put-away Operations: Shuttle AMRs can assist in the put-away process, transporting goods from receiving areas to designated storage locations with speed and accuracy.

Cross-docking: In cross-docking operations, shuttle AMRs facilitate the transfer of goods directly from inbound to outbound docks, reducing the need for intermediate storage.

Goods Transport: Shuttle AMRs excel in transporting goods within a warehouse or distribution center. They can efficiently move items from one location to another, such as from receiving docks to storage areas or from storage areas to order picking stations.

Cold Storage (Cooler) Facilities: Shuttle AMRs are suitable for use in cold storage warehouses, as they can reliably operate in low-temperature environments without fatigue or discomfort.

Quality Control: In quality control processes, shuttle AMRs can transport products to testing or inspection stations, streamlining the quality assurance procedures.

The adaptability, scalability, and efficiency of shuttle AMRs make them valuable assets in modern supply chain management. They offer solutions to various material handling challenges, contributing to increased productivity, reduced labor costs, and improved overall operational performance in diverse industries and warehouse settings.

Case Study: Transforming Warehouse Operations with the Mushiny AMR

Customer Overview:

In a rapidly growing logistics facility, manual material handling processes were becoming a bottleneck. The warehouse faced challenges in meeting the rising demand for order fulfillment efficiently. Labor costs were escalating, and space utilization was not optimized, hindering the facility’s overall productivity.

Solution:

To address these challenges head-on, the warehouse management team decided to embrace automation by implementing the cutting-edge Mushiny M6 Series Shelf AMR. This advanced Autonomous Mobile Robot promised to revolutionize their material handling operations and pave the way for a more efficient and productive future.

Outcome:

The incorporation of the Mushiny AMR brought about a series of transformative outcomes:

Enhanced Efficiency:

The time spent on order picking and replenishment tasks significantly reduced. The AMR’s swift movements and precise navigation streamlined the entire process, boosting overall efficiency.

Optimized Space:

Versatile design allowed for configurable shelves, making the most of the available storage space. This optimization resulted in reduced storage costs and improved warehouse organization.

Improved Safety:

The AMR was equipped with state-of-the-art safety features, including collision avoidance and obstacle detection. This ensured a secure working environment for both the AMR and the warehouse staff.

Scalability:

As the logistics facility continued to expand, it demonstrated its scalability. It seamlessly adapted to the growing demands, catering to the warehouse’s evolving needs.

Conclusion:

With the successful implementation of the Mushiny Autonomous Mobile Robot , the logistics facility underwent a remarkable transformation. The automation solution brought unprecedented efficiency, reduced operational costs, and allowed the warehouse to fulfill orders at an accelerated pace.

The AMR’s impact exceeded expectations, leading the warehouse management team to consider integrating more Mushiny solutions across various aspects of their operations. This case study exemplifies how embracing innovative automation technology can lead to a significant competitive advantage and drive success in today’s fast-paced logistics landscape.